Print & Apply Labeling Systems

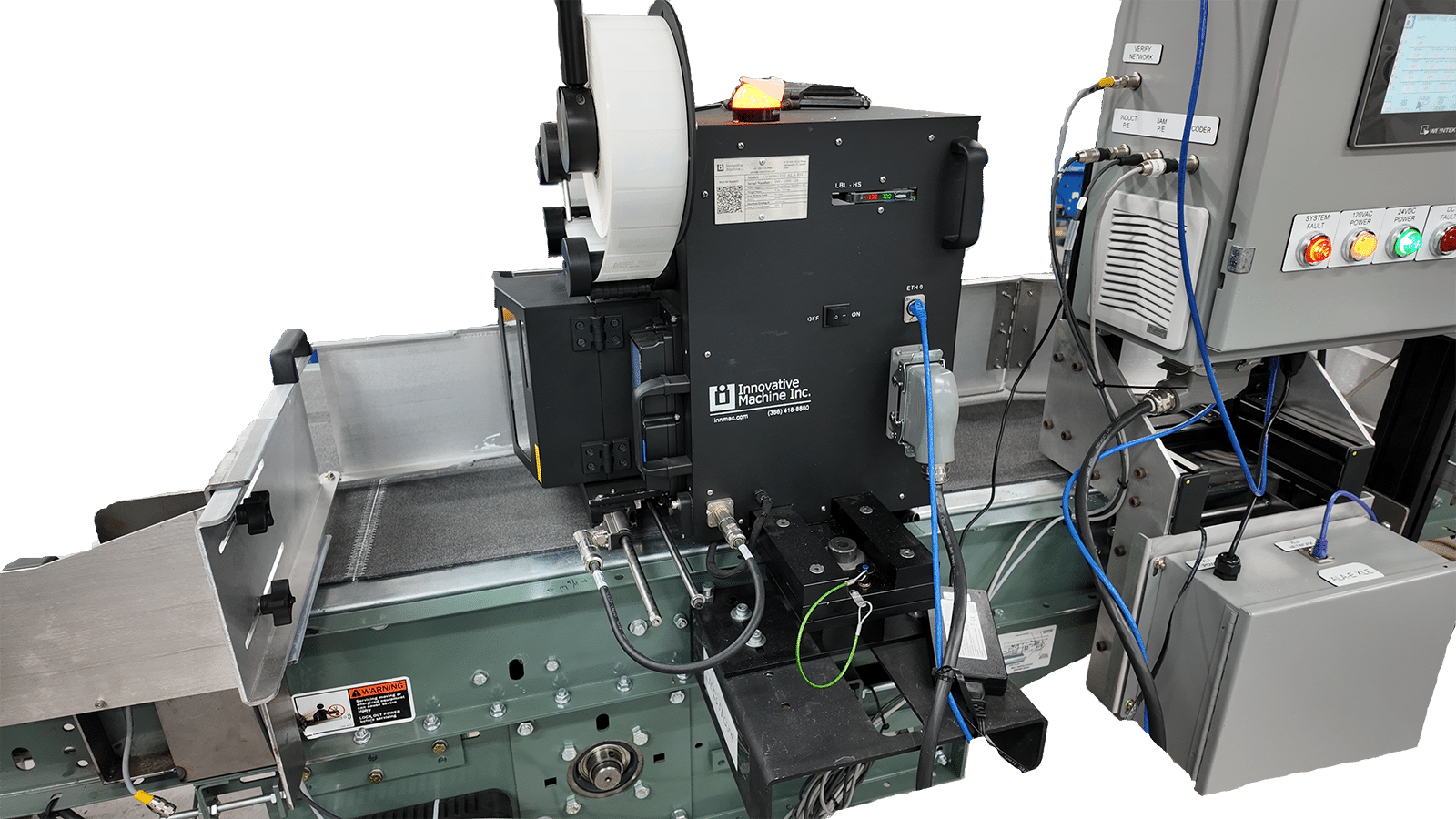

IMI’s UniPrint family delivers fast, precise, and adaptable label application for high-velocity packaging and distribution lines. Air-assist “blow” application keeps placement accurate even when package sizes vary.

IMI creates cutting-edge labeling solutions for industry-defining businesses.

High Throughput

Engineered for thousands of labels per hour with industrial duty cycles.

Precision & Flexibility

Non-contact blow apply maintains accuracy across varying package heights and shapes.

Operator-Friendly

60-second label stock replenishment, clear HMI, and a status light tower with audible alerts.

Model Comparison

| Model | Label Application | Labels/Hour | Conveyor Speed |

|---|---|---|---|

| SA-116 (Side Apply) | Pneumatic (Blow Only) | Up to 6,000 | 600 ft/min* |

| SA-LP-116 (Low Profile Side Apply) | Pneumatic (7″ Extend & Blow) | Up to 4,680 | 140 ft/min |

| SA-EE-124 (Extend Electric Side Apply) | Electric (7″ Extend Full Contact) | Up to 4,680 | 126 ft/min |

| TA-EB-121 (Extend Blow Top Apply) | Pneumatic (7″ Extend & Blow) | Up to 4,680 | 405 ft/min* |

* Using multiple machines & Dependent on Label Size

– All models are RFID capable

SA-116 (Side Apply)

At-a-Glance Specs

- ApplicationSide; Blow Only.

- Placement accuracy±12.7 mm (.5″) at 254 mm (10″) from centerline.

- Package windowVaries by product (contact us)

- Range to product50.8 mm (2″) – 254 mm (10″)

- Label reload time~60 s; RFID-capable

- Dimensions29″ W × 43″ H × 22″ D

- Weight116 lb (52.6 kg)

- PowerAC 100–240 V, 50–60 Hz + 24 VDC (Harting)

- Current (AC/DC)7.5 A / 2 A

- Air70–90 psi, ~6.0 cfm

- Environment23–104 °F, 15–85% RH (non-condensing)

- Conveyor speedUp to 600 ft/min (label-size dependent)

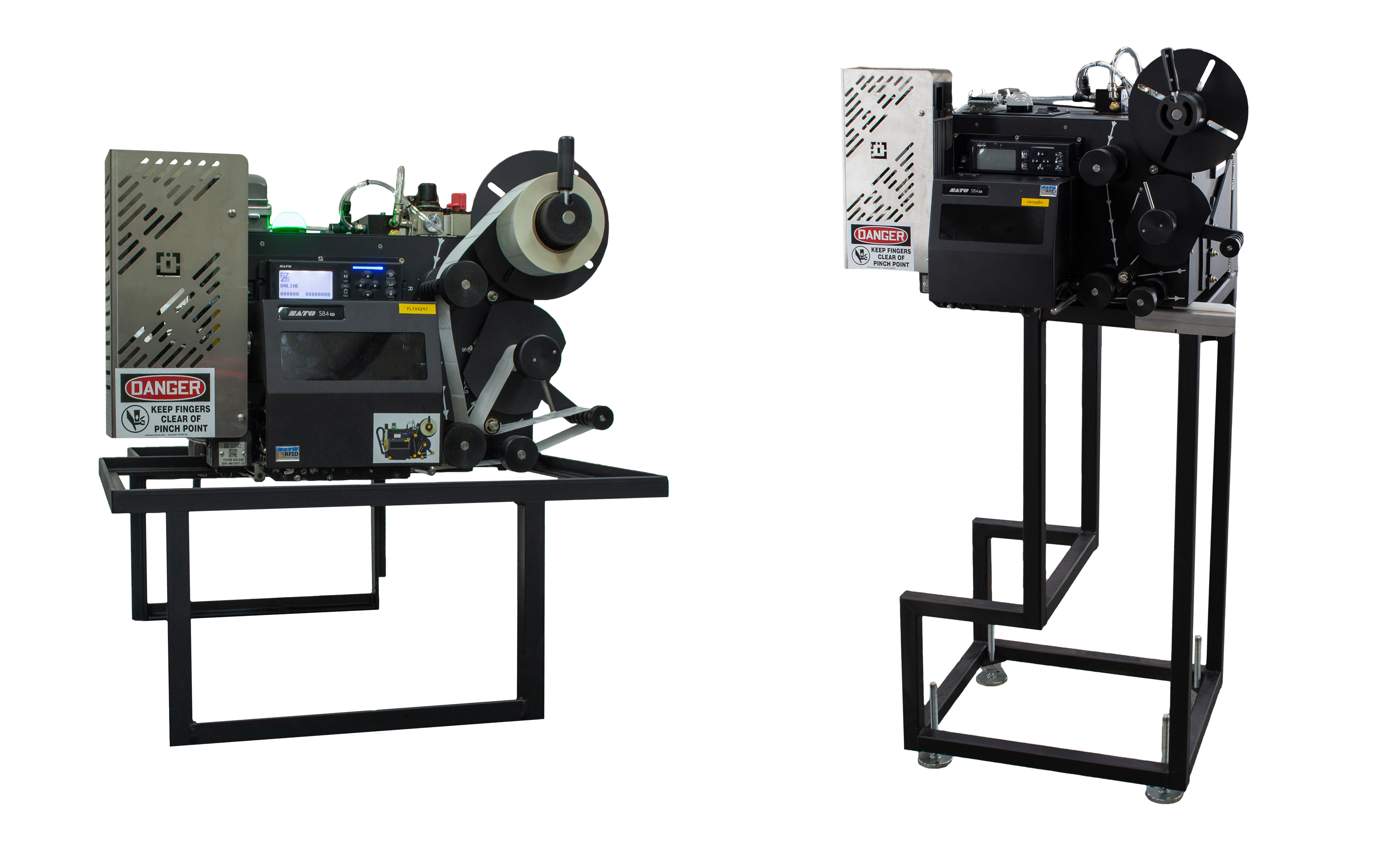

SA-LP-116 (Low Profile Side Apply)

At-a-Glance Specs

- ApplicationSide; Extend with Non-Contact Blow

- Placement accuracy±6.35 mm at 50.8 mm (2″) from centerline

- Package windowVaries by product (contact us)

- Range to product6.35 mm (0.25″) – 50.8 mm (2″)

- Label reload time~60 s; RFID-capable

- Dimensions29″ W × 35″ H × 33″ D

- Weight74 lb (33.6 kg)

- PowerAC 100–240 V, 50–60 Hz + 24 VDC (Harting)

- Current (AC/DC)7.5 A / 2 A

- Air80–85 psi, ~6.0 cfm

- Environment23–104 °F, 15–85% RH (non-condensing)

- Conveyor speed up to 140 ft/min (label-size dependent)

SA-EE-124 (Extend Electric Side Apply)

At-a-Glance Specs

- ApplicationSide; Extend with Full-Contact.

- Placement accuracy±6.35 mm at 50.8 mm (2″) from centerline.

- Package windowVaries by product (contact us)

- Range to product6.35 mm (0.25″) – 50.8 mm (2″).

- Label reload time~60 s; RFID-capable

- Dimensions29″ W × 35″ H × 33″ D

- Weight74 lb (33.6 kg)

- PowerAC 100–240 V, 50–60 Hz + 24 VDC (Harting)

- Current (AC/DC)7.5 A / 2 A

- TypeElectric

- Labeling rateUp to 3,600 labels/hour (≈330 mm/s)

- Conveyor speed up to 126 ft/min (label-size dependent)

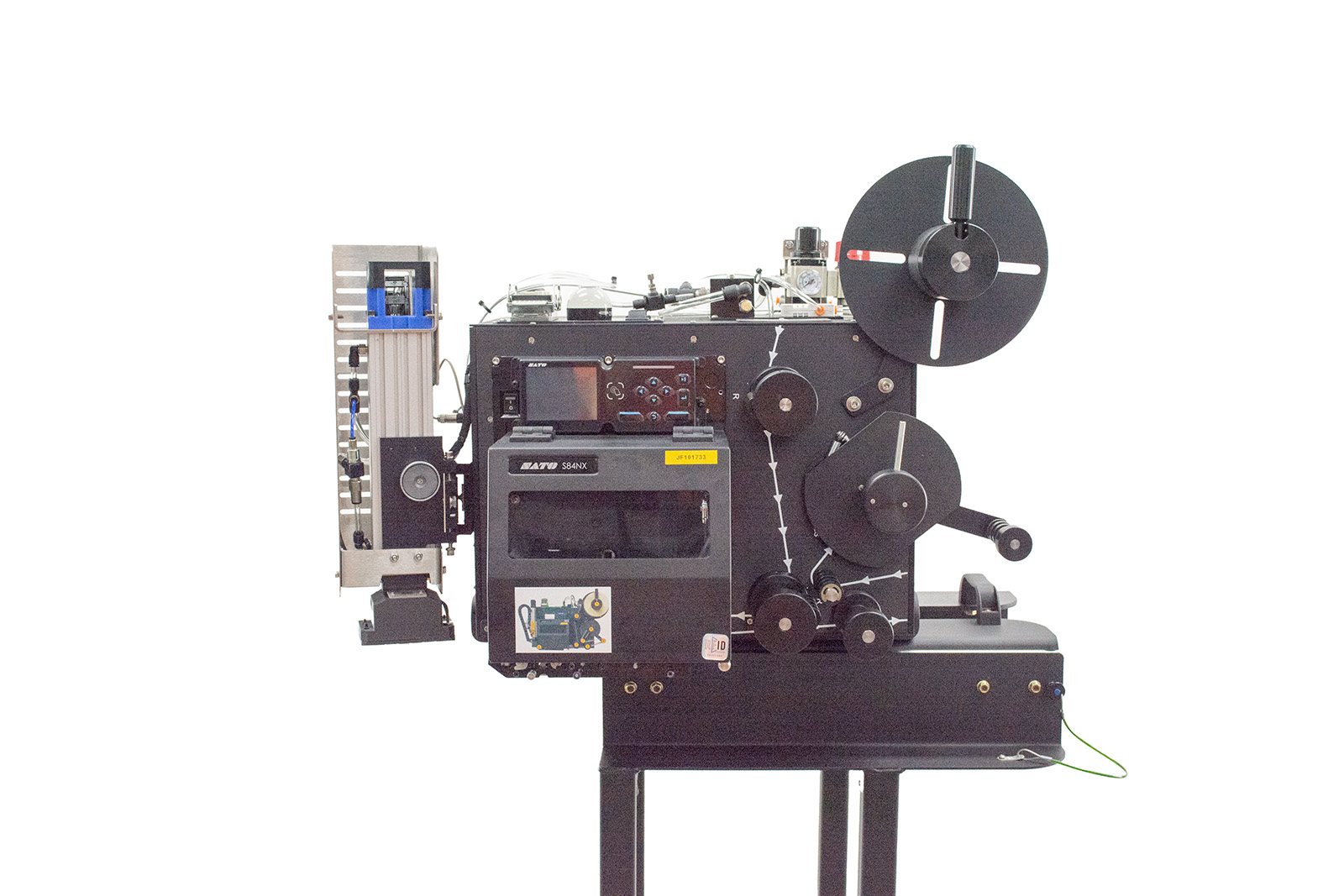

TA-EB-121 (Extend Blow Top Apply)

At-a-Glance Specs

- ApplicationTop; Extend & Blow

- Placement accuracy±6.35 mm at 50.8 mm (2″).

- Package windowVaries by product (contact us).

- Range to product25.4 mm (1″) – 254 mm (10″).

- Label reload time~60 s; RFID-capable

- Dimensions27.812″ W × 19.5″ H × 21″ D

- Weight77 lb (34.9 kg)

- PowerAC 100–240 V, 50–60 Hz + 24 VDC (Harting)

- Current (AC/DC)7.5 A / 2 A

- Air75–80 psi, ~6.0 cfm

- Environment23–104 °F, 15–85% RH (non-condensing)

- Conveyor speedup to 405 ft/min (label-size dependent)

Let’s Match a UniPrint to Your Line

Share your conveyor speed, package range, and label size. We’ll recommend the right head, reach, and orientation.